Here is an excellent tale of why you shouldn’t cut the expert out and do it yourself. We could maybe make this into a blog post.

Granted this customer did use the experts for all the camera installs except they had one camera left over and decided, it wasn’t enough to worry about getting the experts in to run the last wire which was outside the original project scope.

They mounted an external box and just put clips on the wire ends, already cutting corners.

I arrived to add it to the network, they at least understood they weren’t about to configure a VLAN and add the camera to the NVR. I patched it in and they mounted the camera, and we got power but no link.

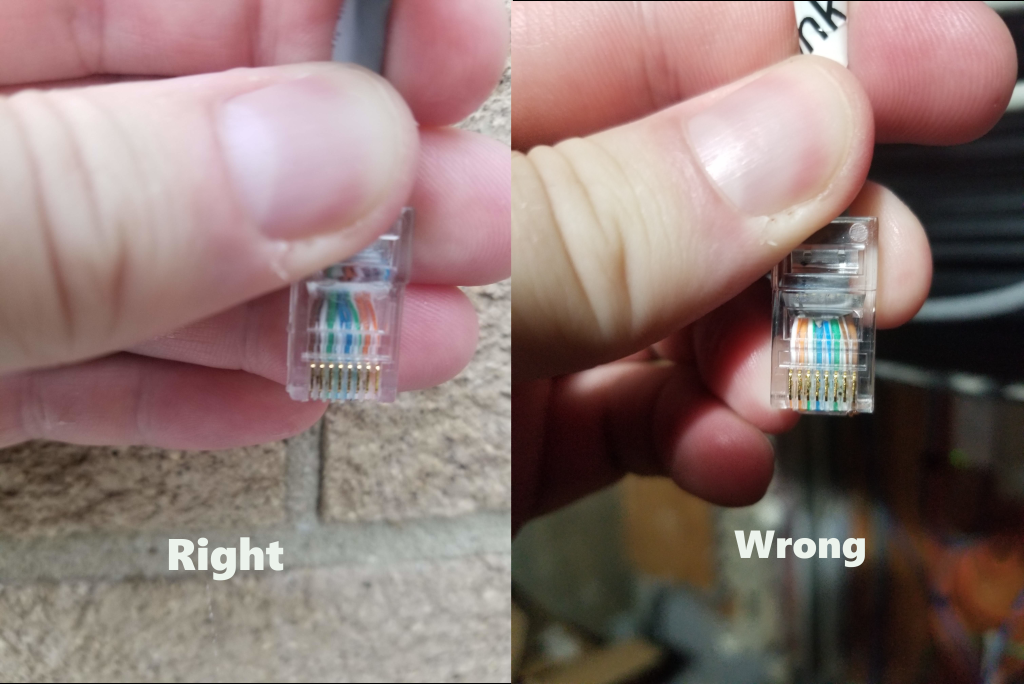

We took the camera back down and examined the clip on both ends.

It turns out they had one side correct and the other side was in reverse order. So pin 1 had the wire for pin 8.

I snipped the end and corrected it. I started to configure the camera and suddenly it went dark. I checked with the customer and he said he just finished mounting it. I told him it just stopped working entirely just a few minutes before he finished mounting it. He reluctantly took the camera down again and when he inspected it, he found that when he put the mounting screws back in they caught on the shielding of the camera cable and shredded it nicely. I found at least two wires completely destroyed where the screw snagged.

After some deliberation, we decided we would snip the pigtail and wire up our own keystone to it.

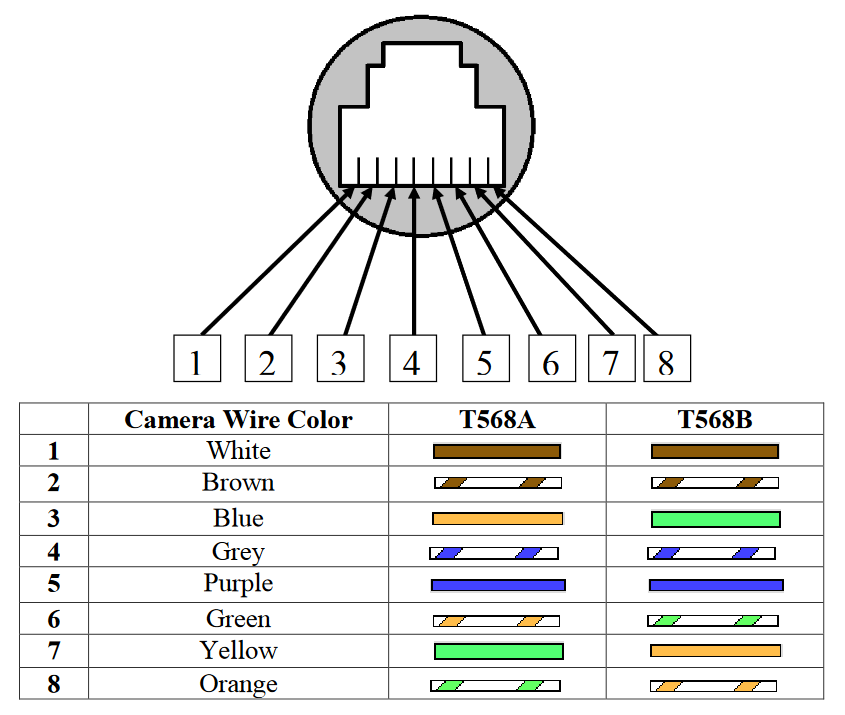

I snipped it and found that this Chinese camera did not have standard ANSI/TIA color coding on the wires. Google to the rescue! We found a PDF on the vendor site that explained what color translated to each color in the 568b standard.

I grabbed a keystone and carefully punched down each wire, we tried the camera and it powered on, but still no data. I examined the keystone and found most of the cables were very loosely connected, it all pulled apart way too easy. The thin wires also were very fragile and the punchdown tool just mangled them badly. After clipping the mangled wires, I was getting more concerned at the ever shortening pigtail we had left. The customer suggested I remove the camera casing to replace the pigtail fully, I don’t think he realizes it’s likely soldered to the board to cut costs and opening it up introduces many other complexities I’d rather not deal with.

I suggested I take it back to the office and ruminate on it, maybe look for a tighter keystone, the customer agreed.

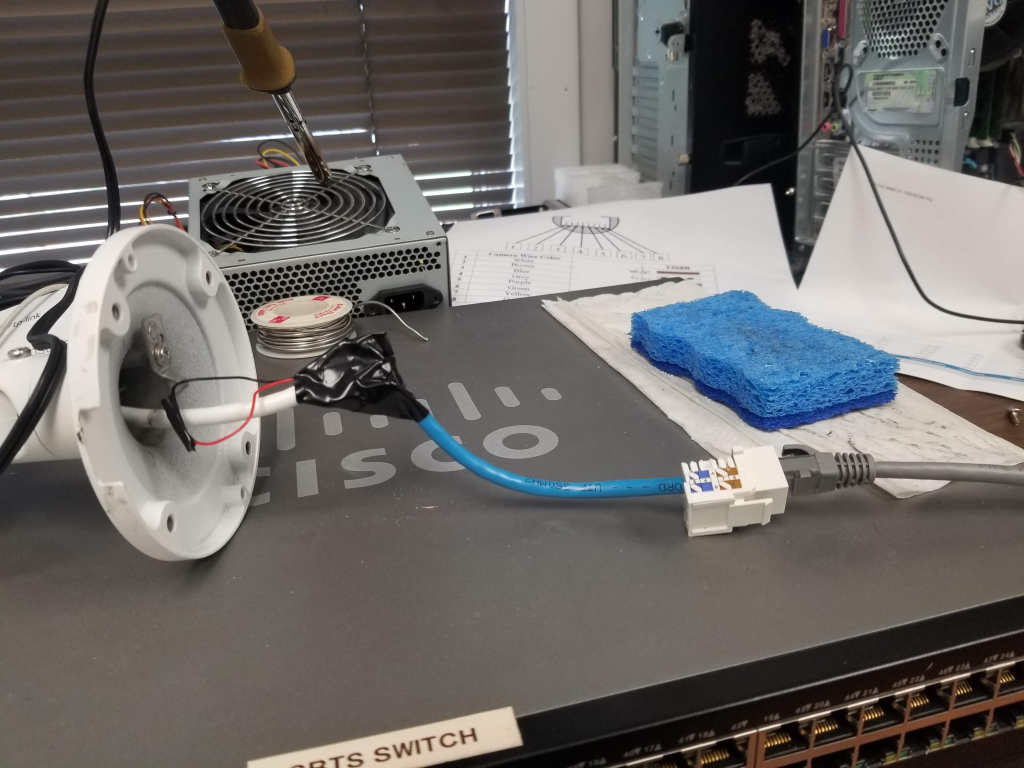

I took the camera and its mangled and short pigtail back to the office.

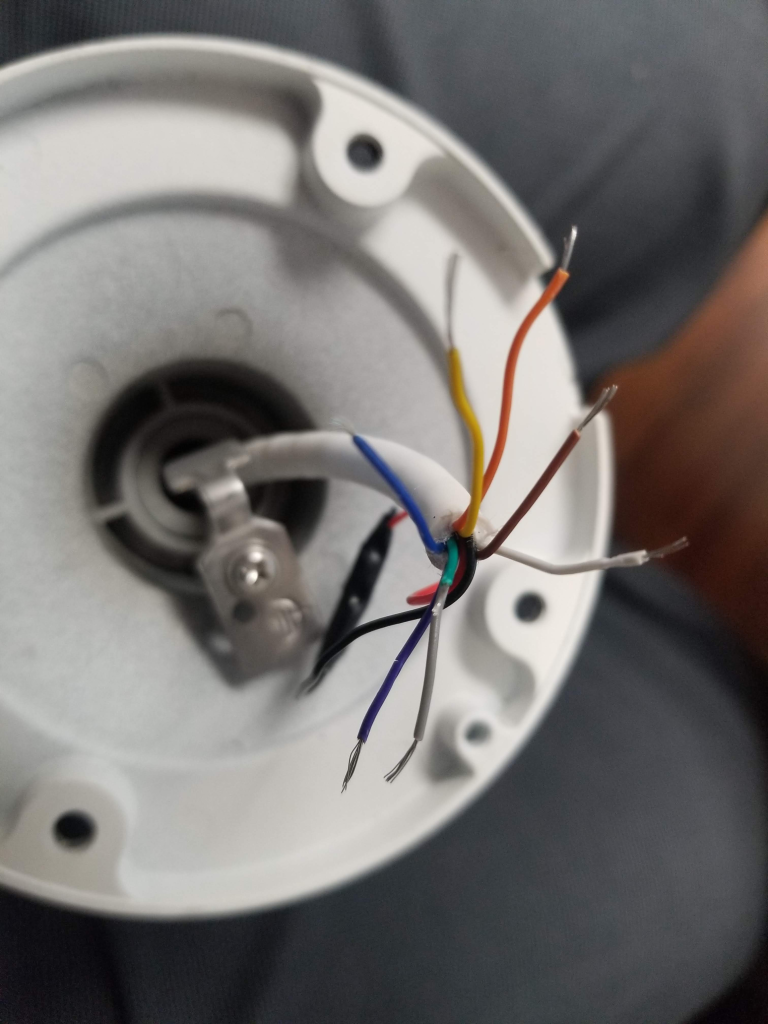

I started researching this camera and repairing a busted pigtail, surely this has happened before, and I found some forums where people discussed the strange wire colors, they also mentioned that most keystones are meant for solid copper twisted pair, not stranded copper twisted pair. I stripped the end of the wires to find that it is stranded but it’s also not copper, it’s some sort of silvery metal.

Considering this is the value line of cameras this wasn’t surprising to me. People were saying it would not be so easy to punchdown because it’s stranded and a smaller gauge, the best option is to solder a pre-wired copper cable with a keystone attached. Luckily we had one in the wiring bag, it was stranded copper, but at least the keystone would then connect to what I assume would be solid copper. Using the smallest gauge on the wire stripper, I careful stripped each cable, I tinned the wires and then attempted to get each pair soldered. I didn’t have any “helping hands” so had to rely on careful positioning to try to get them attached straight, some still are more crossed than flush.

Not to mention, the green wire needed a patch as it had broken off close to the shielding. I had to hold that with some pliers because it was solid copper and would heat up much too quickly to handle with fingers.

This is probably my ninth solder job ever, I should really consider getting a proper station with helping hands and magnifying glass and such, but also it’s my 9th solder job in about 25 years of professional work, so I’m not even the expert on this particular repair, if it doesn’t hold up, we’ll see about shipping it out to one of the laptop repair places.

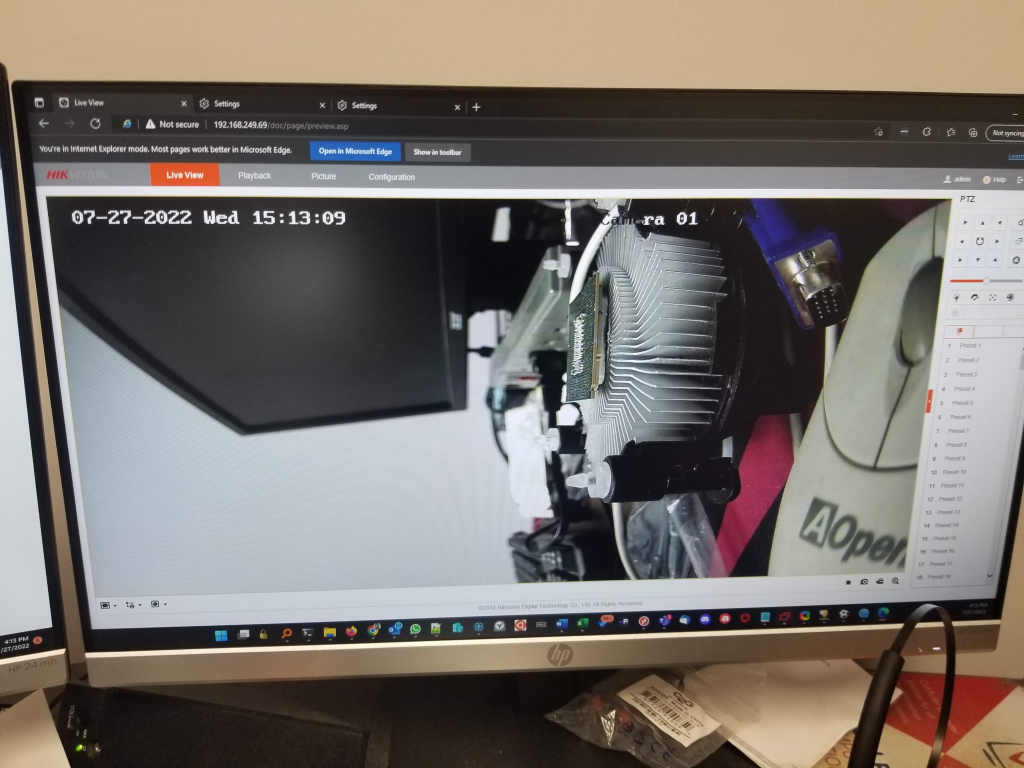

Time to see if the solder job worked out:

Wrapping each wire individually with electrical tape was probably as hard as the soldering, but it’s done and the camera still works.

I’m a little concerned about the mounting process, but I think he’ll be sufficiently careful this time. I’m going to recommend he seals the box with something because that packet won’t hold up well long term.